I got off a call this morning with FPSA-member company CRB, a leading design-build firm that is working with me as the Project Manager for the Pet Food Production Line at October’s Process Expo. After speaking with Jason, I am even more excited to watch us put this line together as he offered up some ideas for new additional innovations in the line in automation.

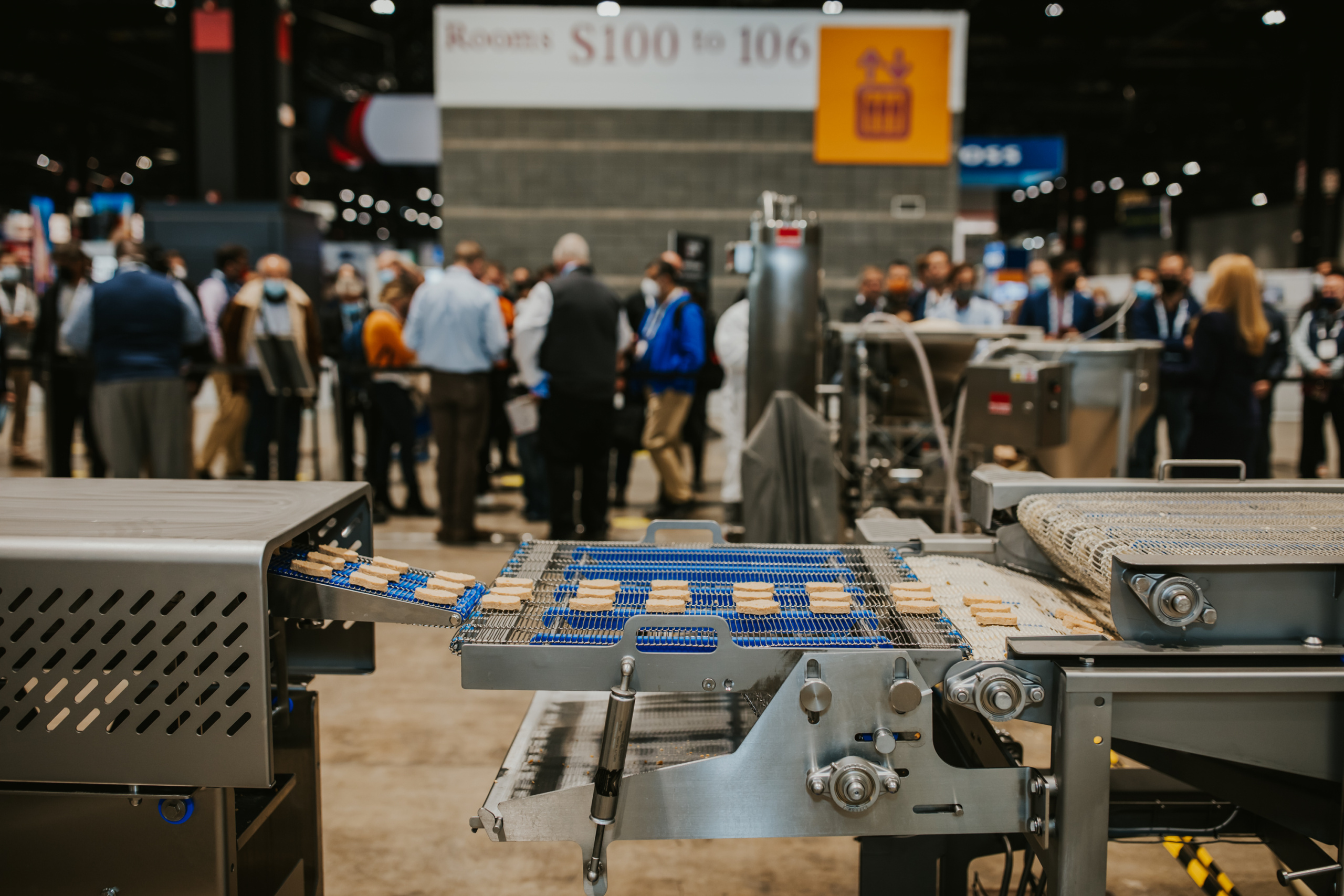

In case you are not familiar with Process Expo’s production lines, FPSA members have been building and running live production line demonstrations with actual food products since 2017. The brainchild of a former Board member of FPSA, the production line program unites OEMs in a year-long project that highlights the latest technologies in processing and packaging during live demonstrations at Process Expo. During these guided demonstrations, the hostesses and participating companies walk the audience through the entire process from the initial collecting of raw ingredients, down to the end with a final product that is packaged, case packed and palletized. These demonstrations serve to demonstrate not just how different manufacturers can work together, but also to display the versatility of said equipment and the myriad of applications that these technologies can be applied to.

In the case of this year’s Pet Treat line, we’ll start with GEA’s grinder and run all the way through JLS’ collaborative robotic palletizer. In between, we’ll also feature a mixer, an extruder/former, a freeze dryer, shuffle conveyor, bucket elevator, net weigher/filler, a bagger, x-ray/checkweigher and case packer and erector. This equipment alone would have been great but in the past six weeks this group decided to add an AI component that will add production monitoring and process validation to the demonstration. On top of that is Jason’s idea to also add other automation features to the line. In short, we are going from just producing some great dog treats, to producing them in the most efficient manner possible that helps the client make the most of their production data and by default, their facilities.

If you have never experienced one of Process Expo’s production lines, I invite you to sign up today to attend this year’s show to see them in action. This year, in addition to our pet treats, we’ll be producing and packaging frozen empanadas and sliced bacon, highlighting a diverse range of processing and packaging technologies. These lines will hold three demonstrations each day of the show, with the goal of showing the Process Expo audience the technologies they might consider in the future to elevate their production to the next level.

I look forward to seeing you in Chicago!

Andy Drennan, FPSA SVP